Home

Since 2003 we design and build electrical diagrams and panels for processes and utilities management in industrial automation facilities and energy distribution systems.

Products overview

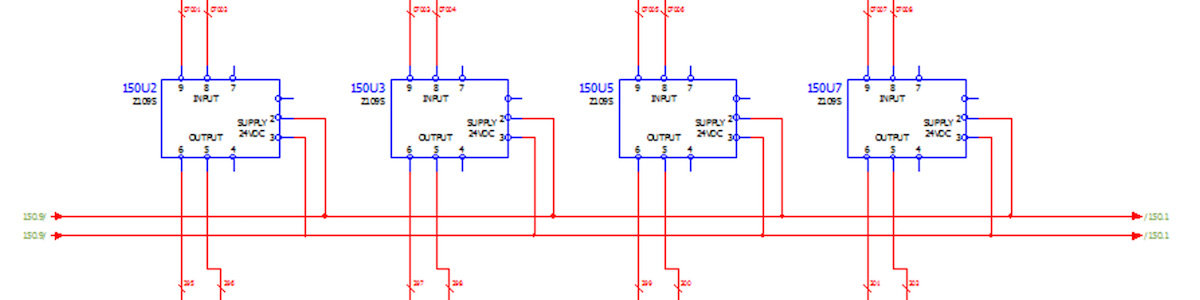

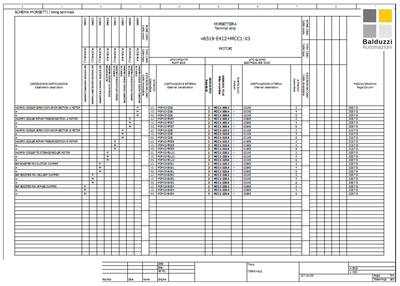

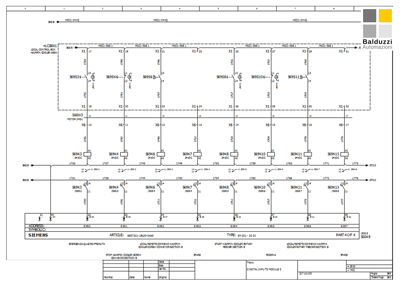

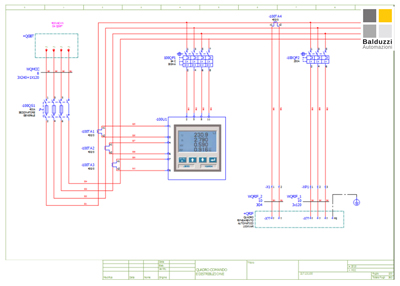

Electrical engineering

Our electrical engineering development team works every day to design wiring diagrams and technical documentation for the electric/electronic systems of industrial machines.

The use of up-to-date CAD software assure you high quality results.

The wiring diagrams include:

We rely on several technical software to build our circuit diagrams.

Specifically, we have two EPLAN P8 workstations that are constantly updated in order to guarantee a cutting-edge service to our customers. To satisfy every customer’s request, we also work on SPAC AUTOMATION and AUTOCAD.

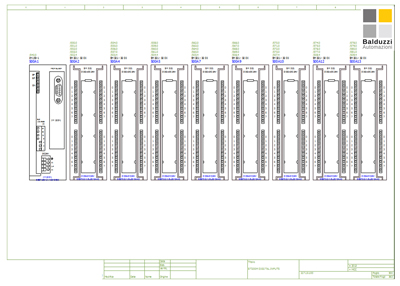

The wiring diagrams include:

- Single-line diagram

- Multi-line diagram

- External layout with architectural and mechanics details

- Internal layout with diagram components references

- PLC structure

- IN/OUT mapping

- Terminal strips

- Symbols index

- Bill of materials of the cables used with their full description

- Bill of materials completed with codes, description and suppliers’ info of each material used

We rely on several technical software to build our circuit diagrams.

Specifically, we have two EPLAN P8 workstations that are constantly updated in order to guarantee a cutting-edge service to our customers. To satisfy every customer’s request, we also work on SPAC AUTOMATION and AUTOCAD.

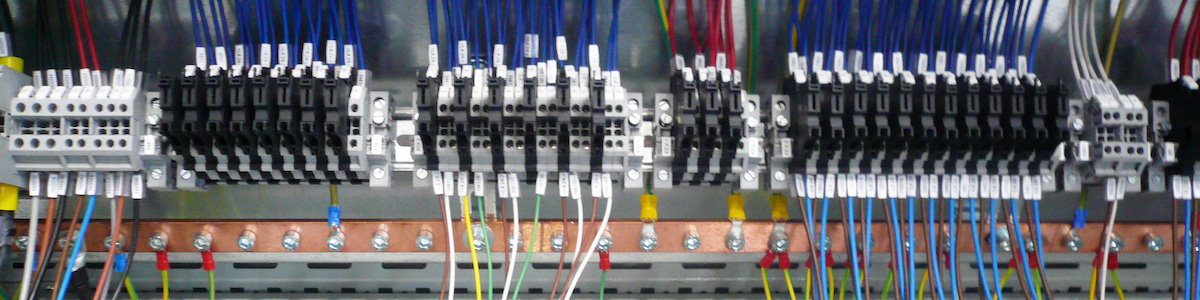

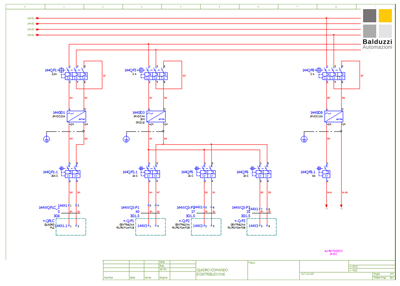

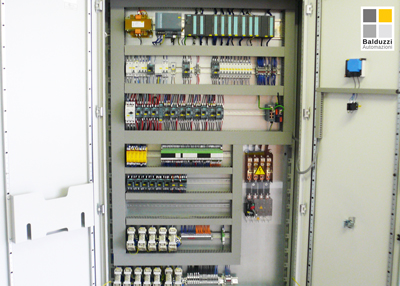

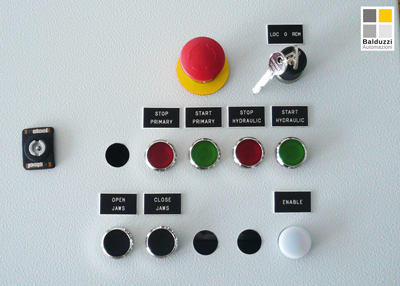

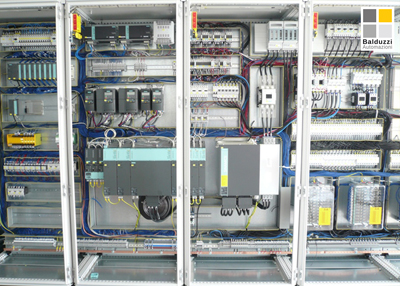

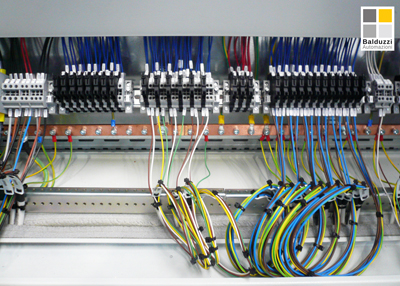

Electrical panels

After a precise analysis and an accurate evaluation of the customer’s needs, we build and modify control panels. Every project is always carried out according to the current national and international regulations.

Our main goal is always to guarantee a high-quality result. For this reason, we are really meticulous in all the different phases of our process from assembling to wiring and component labelling. All the materials used are from the best brands in the business (ABB, Finder, Phoenix, Rittal, Siemens, Schneider), providing a high-quality product with easy reachable spare parts.

Years of experience and high technical competences are our receipt to offer to our customers higher quality products, avantgarde technical solutions and a right quality-price ratio.

Since May 2018 a new and bigger laboratory allows us to build:

All the electrical panels are delivered complete with wiring diagrams and technical documentation of the project, tests certificate and conformity declaration (CE mark).

If required, we also handle the installation on site of the control panel.

Our main goal is always to guarantee a high-quality result. For this reason, we are really meticulous in all the different phases of our process from assembling to wiring and component labelling. All the materials used are from the best brands in the business (ABB, Finder, Phoenix, Rittal, Siemens, Schneider), providing a high-quality product with easy reachable spare parts.

Years of experience and high technical competences are our receipt to offer to our customers higher quality products, avantgarde technical solutions and a right quality-price ratio.

Since May 2018 a new and bigger laboratory allows us to build:

- Automation control panels

- Distribution control panels

- PLC software

All the electrical panels are delivered complete with wiring diagrams and technical documentation of the project, tests certificate and conformity declaration (CE mark).

If required, we also handle the installation on site of the control panel.

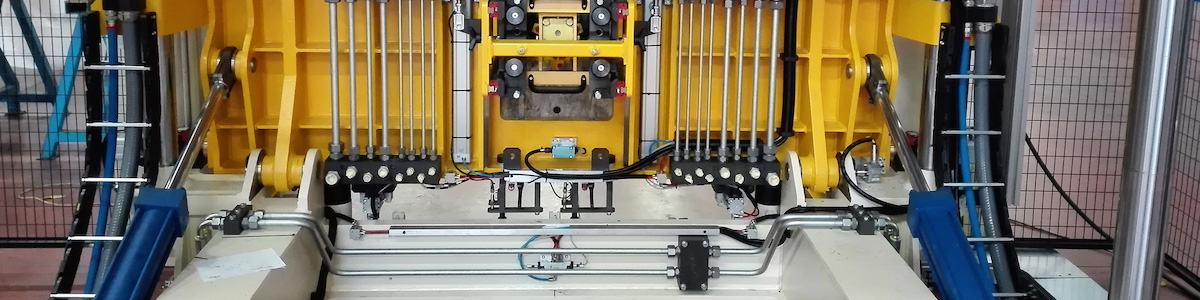

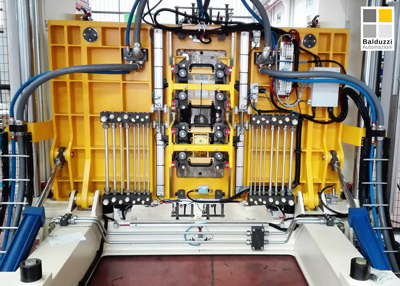

On-board machine systems

During the years we gained knowledge and high specialization in the production of on-board machine wiring for industrial facilities (industrial machinery and production lines) in different industrial sectors.

What we deeply believe to be our strength is the technical assistance during all the phases of the project, with a strong problem-solving attitude from its early draft to the final tests and first run (even abroad).

We actively participate during all the steps of the on-board machine project, not only as executors, but as technicians able to manage the critical aspects that can be found along the way, undertaking immediate actions to solve them and assuring to the customer the expected final result.

As a consequence, we are confident to provide high technology solutions with the correct quality-price ratio.

The deep knowledge of the current regulations as well as of the materials, the on site organizational capabilities and our flexibility help us to avoid many logistic difficulties. We are able to provide to the customer operational continuity in the shortest time possible, in order to reduce the machine downtime.

What we deeply believe to be our strength is the technical assistance during all the phases of the project, with a strong problem-solving attitude from its early draft to the final tests and first run (even abroad).

We actively participate during all the steps of the on-board machine project, not only as executors, but as technicians able to manage the critical aspects that can be found along the way, undertaking immediate actions to solve them and assuring to the customer the expected final result.

As a consequence, we are confident to provide high technology solutions with the correct quality-price ratio.

The deep knowledge of the current regulations as well as of the materials, the on site organizational capabilities and our flexibility help us to avoid many logistic difficulties. We are able to provide to the customer operational continuity in the shortest time possible, in order to reduce the machine downtime.

Services

We provide to the customer a complete service, which combines our products with a high professional technical assistance and consulting.

Years of experience, the continuous updating and the cooperation with the different professionals in the sector allow us to guarantee to our customers high professionality, solid skills and services handled in every detail.

Years of experience, the continuous updating and the cooperation with the different professionals in the sector allow us to guarantee to our customers high professionality, solid skills and services handled in every detail.

Machine securing complete service

The service includes the risk evaluation analysis to secure the machinery, which is done by trustworthy external consultants with whom we are cooperating for years. The revamping actions to secure already in use machines are also included.

Existing panel modification and supplementing

We are available to study changes, supplementing and partial rebuilding of already existing control panels, with the aim of modernize the industrial systems always according with legal standards and requirements.

Existing wiring diagrams modification and supplementing

Our service includes transcription, changes and updates of outdated wiring diagrams, making them compliant to the modern regulations and ready to answer to the current needs of computerization.

On request we also translate existing circuit diagrams from paper to digital.

On request we also translate existing circuit diagrams from paper to digital.

Cost analysis consulting

For a third party, we perform consulting and analysis services during the quote steps of projects in medium and big dimensions facilities.

The Company

Founded on the twenty-year experience of the owner, the firm born in 2003 as an individual company performing services of design and assembly of control panels for automation and distribution systems.

It started a path of collaboration with well-known industrial companies both in the electrical engineering development (electrical engineer, PLC software, technical documentation) as well as in the design of unique automation control panels with their on-board machine installation.

Different were the sectors in which the firm operated:

In 2012 the Balduzzi automazioni snc was born as an answer to a continuously changing market. With a dynamic and elastic structure and passion for our work, we committed to an always increasing customer satisfaction.

Thanks to our professional competences, the company faced and overcame the economical crisis with energy and solidity, acquiring new clients and expanding its market. For this reason, alongside the team of independent workers cooperating with the company, the first employee was hired into our technical staff in 2016.

As the work increased, in 2018 the company began an expansion path, employing new team members and moving to a larger location, with an improved office and an enlarged workshop. As the relocation ended in May, in June the Balduzzi Automazioni srl was formed.

To date, the company includes 3 partners, 2 employees and several independent collaborators.

It started a path of collaboration with well-known industrial companies both in the electrical engineering development (electrical engineer, PLC software, technical documentation) as well as in the design of unique automation control panels with their on-board machine installation.

Different were the sectors in which the firm operated:

- Water treatment systems

- Automotive production lines

- Air treatment systems

- Iron and steel industry machineries

- Nautical sites

- Cogeneration plants

In 2012 the Balduzzi automazioni snc was born as an answer to a continuously changing market. With a dynamic and elastic structure and passion for our work, we committed to an always increasing customer satisfaction.

Thanks to our professional competences, the company faced and overcame the economical crisis with energy and solidity, acquiring new clients and expanding its market. For this reason, alongside the team of independent workers cooperating with the company, the first employee was hired into our technical staff in 2016.

As the work increased, in 2018 the company began an expansion path, employing new team members and moving to a larger location, with an improved office and an enlarged workshop. As the relocation ended in May, in June the Balduzzi Automazioni srl was formed.

To date, the company includes 3 partners, 2 employees and several independent collaborators.

Our mission

Experience, professionalism and technical avant-garde are our company pillars.

We truly believe in the added value of artisan work and in the importance of product customization.

If you consider competence an important key to success, we are your ideal partner.

We provide high-level products and services, putting our thirty-year expertise at the customer’s service. Technical know-how built upon years of experience in the field and continuous formation, problem solving skills and high flexibility allow us to provide the highest degree of product customization and machinery prototyping. We don’t offer standard and mass-produced products, but unique and ad-hoc services.

Balduzzi automazioni is not just a supplier for its customers, but a strategic partner.

We truly believe in the added value of artisan work and in the importance of product customization.

If you consider competence an important key to success, we are your ideal partner.

We provide high-level products and services, putting our thirty-year expertise at the customer’s service. Technical know-how built upon years of experience in the field and continuous formation, problem solving skills and high flexibility allow us to provide the highest degree of product customization and machinery prototyping. We don’t offer standard and mass-produced products, but unique and ad-hoc services.

Balduzzi automazioni is not just a supplier for its customers, but a strategic partner.

Monday - Friday 8.30 - 17.30

Monday - Friday 8.30 - 17.30